In modern manufacturing, machining efficiency and precision are at the core of a company’s competitiveness. However, when faced with complex materials and unique machining requirements, standard tools often fail to meet customers’ personalized needs. As a company specializing in custom tool solutions, SDFTools is dedicated to providing tailored solutions for our clients. Today, we will share a successful case study showcasing how our Internal Coolant Flat Bottom Step Drill helped a customer overcome machining challenges and significantly optimize their production process.

Customer Requirements Background

A leading aerospace component manufacturer approached us with a challenging machining problem:

- Material Characteristics : The customer primarily machined aluminum alloys and stainless steel, which are prone to built-up edges, affecting surface quality.

- Workpiece Structure : The workpieces featured numerous curved surfaces, inclined planes, and thin plates, requiring flat-bottomed holes on these complex surfaces.

- Efficiency Needs : Due to high order volumes, the customer sought to reduce machining steps, improve overall efficiency, while ensuring machining accuracy and stability.

- Pain Points : Traditional drills frequently caused burrs, misalignment, and poor chip evacuation, impacting product quality and production efficiency.

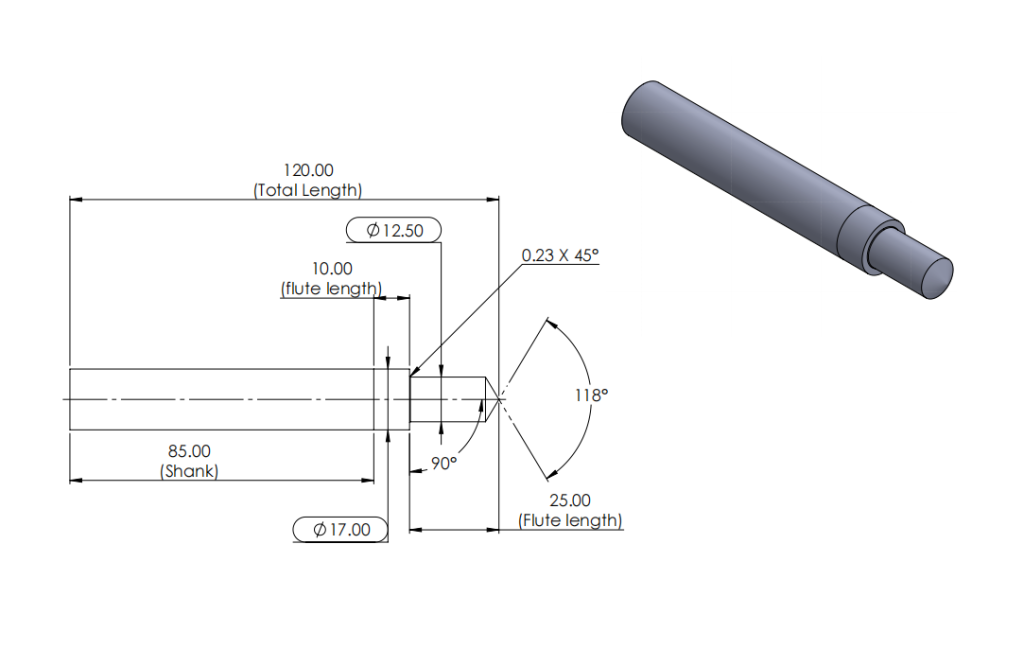

To address these needs, we designed a custom Internal Coolant Flat Bottom Step Drill , perfectly solving these issues.

Product Design Solutions

Based on the customer’s specific requirements, we focused on the following design aspects:

1、Flat Bottom Design (Flat Bottom)

- The flat bottom cutting edge allows for direct machining of flat-bottomed holes on curved surfaces, inclined planes, or thin plates without additional processes.

- This design effectively prevents misalignment common with traditional drills on complex surfaces, enhancing machining accuracy.

2、Internal Coolant Channels (Internal Coolant)

- The tool features internal coolant channels that enable efficient chip evacuation and heat dissipation during machining.

- Coolant directly reaches the cutting point, reducing built-up edges and extending tool life while ensuring a stable machining process.

3、Step Drill Functionality (Step Drill)

- The ability to form multi-level holes in one operation significantly reduces tool changes, simplifying the machining process.

- For the customer’s need for multiple hole diameters, this tool completes different diameter stepped holes in a single setup, greatly improving efficiency.

4、Optional Edge Honing Treatment

- To meet the customer’s demand for extended tool life, we provided an optional honing treatment to enhance edge strength and wear resistance.

Application Results

After practical testing and batch production verification, this Internal Coolant Flat Bottom Step Drill demonstrated outstanding performance:

- Improved Machining Efficiency : Compared to traditional drills, machining time was reduced by approximately 30%. The multi-level hole design eliminated frequent tool changes, reducing cycle times.

- Enhanced Precision : The flat bottom design ensured flat-bottomed holes met the customer’s stringent standards, with no misalignment on complex surfaces.

- Better Surface Quality : The combination of internal coolant and edge honing treatment effectively minimized burrs and built-up edges, resulting in smooth, flawless surfaces.

- Extended Tool Life : Thanks to efficient cooling and enhanced edge durability, the tool’s lifespan increased by over 50% compared to conventional drills.

The customer highly praised the performance of this custom tool and expressed their intention to continue collaborating with us on developing more customized solutions.

Why Choose SDFTools?

As a company specializing in custom tool solutions, SDFTools’ core strengths include:

- Deep Customization Capability : We provide end-to-end services from design to production based on specific customer needs, ensuring every tool perfectly fits its application.

- Professional Technical Support : Our engineering team has extensive industry experience and can quickly respond to customer needs, offering optimal solutions.

- High-Quality Manufacturing : Advanced processing technologies and strict quality control systems ensure each tool delivers exceptional performance and reliability.

Contact Us to Customize Your Perfect Tool!

If you face similar machining challenges or wish to optimize your current production process, feel free to contact us! SDFTools will provide professional technical support and customized tool solutions tailored to your needs.

🌐 Website: www.sdftools.com

📧 Email: sdfgroup@sdftools.com

📱 WhatsApp: +65 89420188

👥 LinkedIn: www.linkedin.com/company/shengdefu-precision-tools-co-ltd

Let’s build a more efficient and precise machining future together!