Description

Ultra-Hard Left-Hand Thread Mill | ALTiSiN Coated | Two-Row Teeth Precision

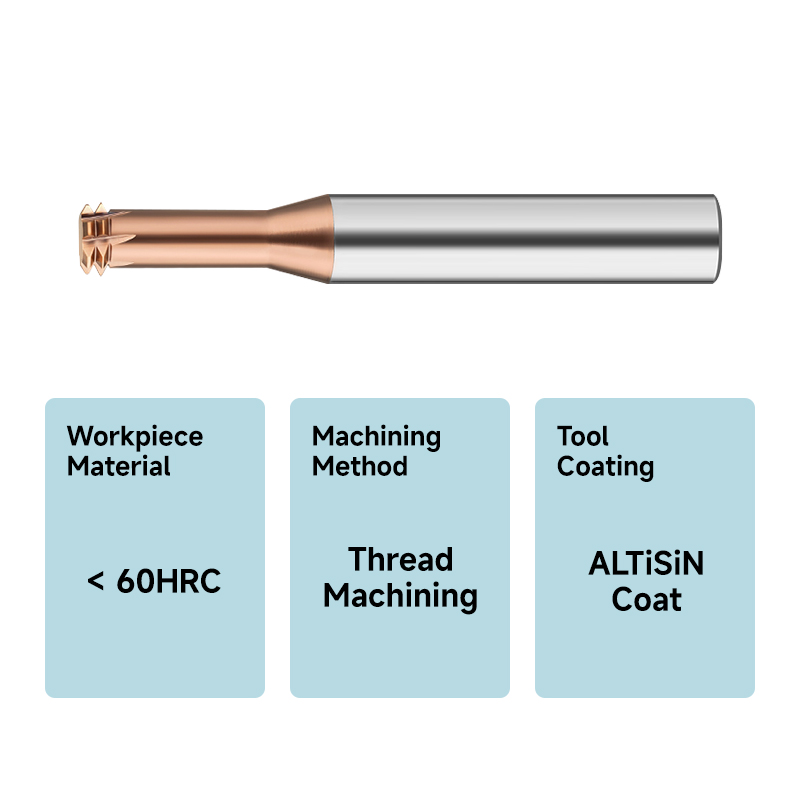

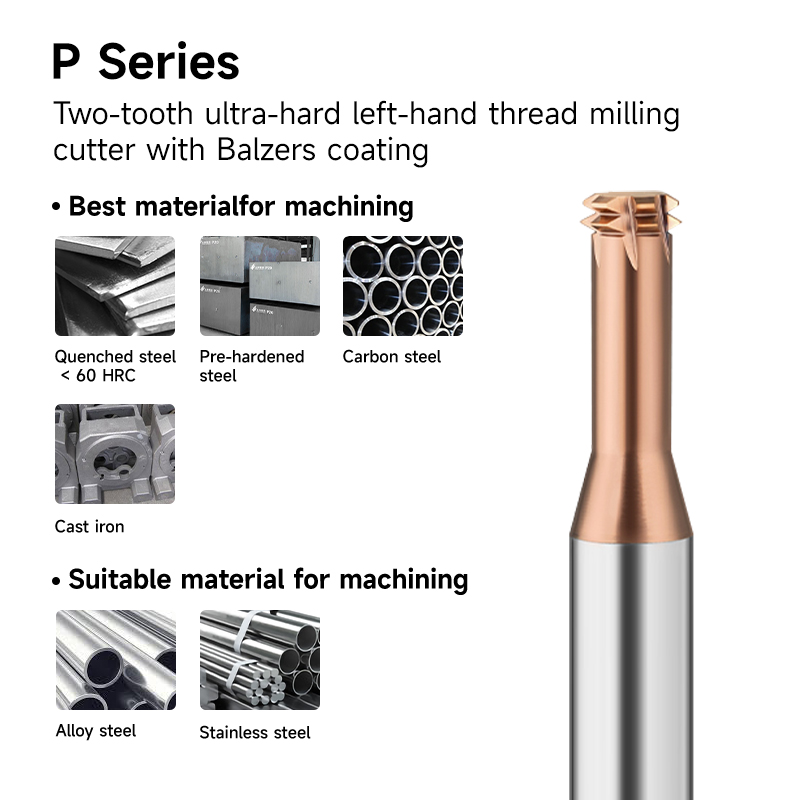

Engineered for machining hardened steels and exotic alloys, the SDF-P Series left-hand thread mill combines German carbide technology with Balzers ALTiSiN coating to deliver unmatched performance in high-stress applications:

Dual-Row Cutting Innovation

- First Row (Roughing): Short teeth remove 70% material rapidly with low cutting force

- Second Row (Finishing): Full-profile teeth achieve Ra0.8μm finish in HRC60+ dies

- Left-Hand Advantage: Reverse spindle rotation stabilizes deep cavity threading (Ideal for injection molds)

Industrial-Proven Performance

- Base Material: 0.4μm German tungsten carbide (ISO K30-K40 grade)

- Coating: BALZERS ALTiSiN (3μm | 3,500HV | 900°C oxidation resistance)

- Certified Precision: ZOLLER inspected ≤0.008mm runout (ISO 2768-m compliant)

- Speed & Feed: 80-120m/min in H13 tool steel | 0.03-0.05mm/tooth

Mission-Critical Applications

- Automotive molds (NAAMS standard M18-M36 left-hand threads)

- Aerospace titanium fasteners (NASM 8879 compliant)

- Medical device screws in 17-4PH stainless steel

Smart Manufacturing Services

- 3D Models On-Demand: Get STEP/IGES files with tolerance annotations in 4h

- Regrinding Program: 5X tool reuse cycle with recoating (60% cost saving)

- Global Stock: 500+ left-hand variants (M2-M48) ready to ship

[表格 id=8 /]