In modern manufacturing, machining high-strength alloy steel has always been a challenge in the precision manufacturing field. These materials are not only extremely hard (e.g., HRC50-55) but also demand stringent requirements for machining accuracy and surface quality. Recently, we successfully helped a high-end component manufacturer solve numerous issues in reaming high-strength alloy steel. Through customized tooling, we significantly improved the customer’s production efficiency and economic benefits. Below is a detailed case study of this project.

Customer Needs and Pain Points

1、Existing Tools Fail to Meet Production Requirements

- The customer was machining high-strength alloy steel with a hardness of HRC50-55. The standard reamers they used had a lifespan of only 800 holes, and the hole tolerance fluctuated by ±0.01mm, far exceeding the required ±0.005mm.

- Frequent chatter during machining resulted in a hole wall roughness of Ra > 1.6μm, while the customer required Ra ≤ 0.8μm.

2、High Trial-and-Error Costs with No Results

- The customer tested general-purpose reamers from four different suppliers, conducting a total of 27 trials. This effort cost approximately 20,000 RMB in tool procurement and resulted in over 10 hours of downtime, yet the problem remained unresolved.

3、International Brand Solutions Lack Cost-Effectiveness

- A global tool manufacturer proposed a custom solution with a unit price 300% higher than the market average, a lead time of 3-4 weeks, and a mandatory annual purchase commitment, which the customer found unacceptable.

Faced with these challenges, the customer urgently needed an efficient, stable, and cost-effective custom reamer.

Our Solution

Based on the customer’s pain points, we developed a phased technical approach, addressing each issue step by step—from geometry design to material selection and coating optimization:

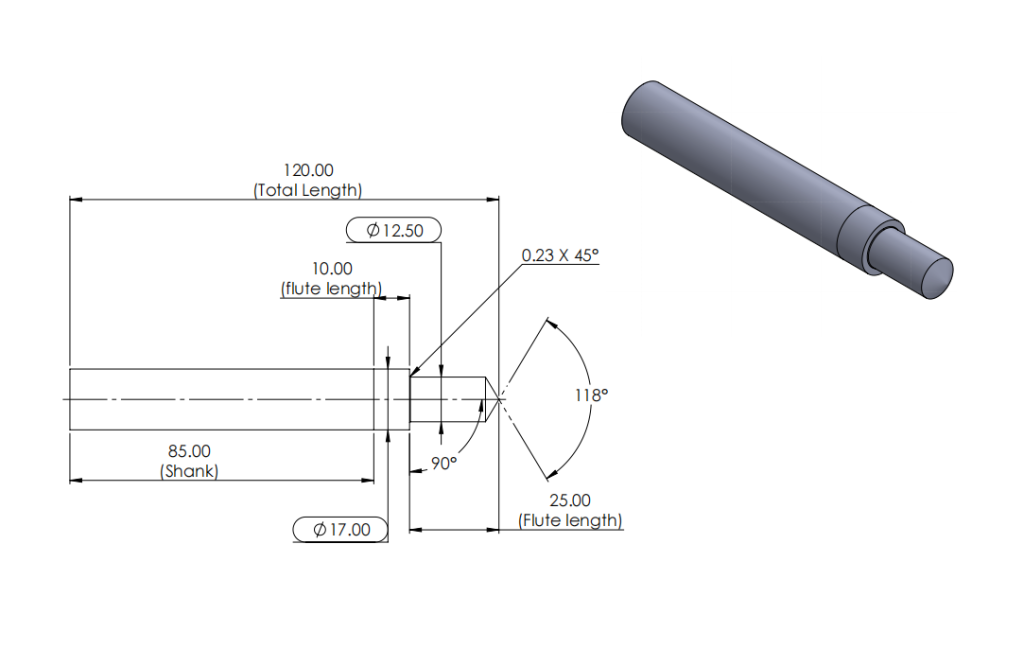

1、Customized Design

- Adjusted tool geometry: Reduced the rake angle from 5° to -3° to minimize tool wear and optimized the helix angle from 10° to 15° to improve chip evacuation.

- Adopted a non-standard land width design (reduced from 0.1mm to 0.05mm) to reduce friction with the hole wall and enhance surface finish.

2、Material Testing:Tested three types of carbide substrates:

- Standard YG8: Lifespan of 750 holes (baseline);

- Ultrafine-grain UM40: Lifespan increased to 1,000 holes;

- TF15 with TaC additive: Lifespan reached 1,400 holes (final selection).

3、Coating Optimization:Compared AlTiN, TiSiN, and DLC coatings:

- AlTiN: Insufficient heat resistance, lifespan of 750 holes;

- TiSiN (nano-multilayer): Improved heat resistance, lifespan of 1,000 holes;

- TiAlN composite coating: Lifespan exceeded 1,500 holes (final solution).

Problem-Solving Process

1、First Prototype and Testing

- We delivered the first batch of 10 reamers (TF15 substrate + TiAlN composite coating). The customer tested them and achieved a lifespan of 1,000 holes with a surface roughness of Ra 0.8μm, but slight chatter marks were still present.

2、Second Optimization

- Adjusted the edge honing size (from 0.03mm to 0.02mm) and increased the number of internal coolant holes (from 2 to 4), eliminating chatter marks and extending the lifespan to 1,200 holes.

3、Final Validation

- After three consecutive batches of testing, the average lifespan stabilized at 1,500±50 holes, with hole tolerances controlled within ±0.005mm. Production line efficiency improved by 30%.

Customer Feedback and Results

- Problem Solved : The customer terminated testing with other suppliers and signed an annual procurement agreement with us, placing repeat orders of 200 reamers per month.

- Cost Comparison : The cost per hole dropped from 1.2 RMB to 0.4 RMB, saving approximately 100,000 RMB annually.

Lessons Learned and Industry Standardization Recommendations

1、Technical Insights

- Machining high-strength materials requires synergy among “substrate-coating-geometry.” Ultrafine-grain substrates combined with composite coatings provide long-term solutions.

- A helix angle greater than 10° significantly improves chip evacuation for high-hardness materials.

2、Customer Service Experience

- Rapid response (providing solutions within 72 hours) and data-driven validation (providing comparative test reports) are key to winning customer trust.

3、Standardization Recommendations

For reaming HRC50+ materials, we recommend the following industry standards:

- Substrate: Ultrafine-grain carbide (grain size ≤ 0.5μm);

- Coating: TiAlN composite coating (thickness 3-4μm);

- Geometry Parameters: Helix angle 15°-20°, land width ≤ 0.1mm.

Case Value

Through deep customization and scientific trial-and-error, we not only solved the customer’s reaming challenges with high-strength alloy steel but also broke the monopoly of international brands in the high-end custom tooling market. This provides a reusable localized solution for similar high-difficulty reaming applications.

Contact Us to Customize Your Perfect Tool!

If you face similar machining challenges or wish to optimize your current production process, feel free to contact us! SDFTools will provide professional technical support and tailored tooling solutions.

🌐 Website: www.sdftools.com

📧 Email: sdfgroup@sdftools.com

📱 WhatsApp: +65 89420188

👥 LinkedIn: www.linkedin.com/company/shengdefu-precision-tools-co-ltd

Let’s build a more efficient and precise machining future together!