At SDFTools, we take pride in delivering innovative, tailored solutions to our partners. Recently, we introduced the Carbide Reamer 6FL-Coolant , a cutting-edge hard carbide reamer designed for high-efficiency and high-precision machining applications. This custom tool has already proven its value in real-world production environments, helping our customers achieve significant improvements in performance and cost savings. Here’s how this groundbreaking solution came to life.

The Challenge: Meeting Demanding Machining Needs

Our client, a leading automotive parts manufacturer, faced several challenges in their production process:

1、Material Complexity

- The client was machining high-hardness materials such as titanium alloys and stainless steel, which are prone to heat buildup and rapid tool wear.

- Surface finish requirements were stringent, with a target roughness of ≤Ra0.4.

2、Inefficiencies with Standard Tools

- Conventional reamers struggled to maintain consistent tolerances, leading to frequent tool changes and increased downtime.

- Single-piece processing times were too long, limiting overall throughput.

3、Customization Necessity

- Off-the-shelf tools failed to address the unique demands of their specific materials, equipment, and production goals.

The client needed a customized solution that could deliver superior performance while reducing costs and improving efficiency.

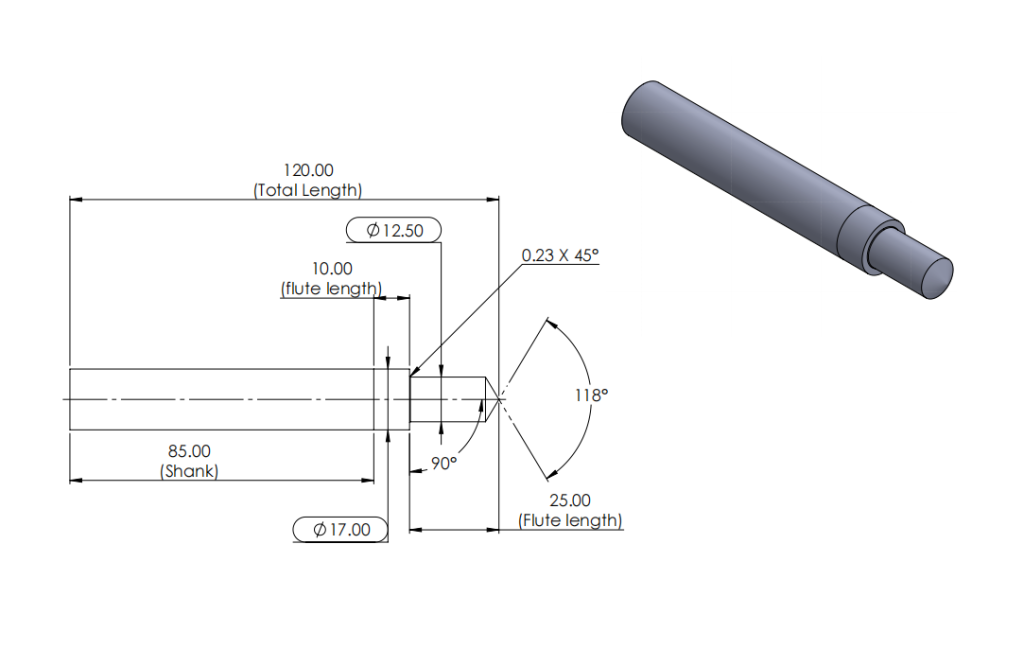

The Solution: Carbide Reamer 6FL-Coolant

To address these challenges, we developed the Carbide Reamer 6FL-Coolant , a fully customized tool designed to meet the client’s exact requirements. Here’s what makes this reamer stand out:

- The Solution: Carbide Reamer 6FL-Coolant:The 6-flute geometry optimizes cutting speed and chip evacuation, significantly reducing cycle times and boosting productivity.

- Internal Coolant Technology:Precision coolant delivery directly to the cutting edge minimizes heat buildup, extends tool life, and reduces the risk of thermal deformation in the workpiece.

- 100% Customization:From coating technologies to edge geometries, every aspect of the tool was tailored to match the client’s specific materials and machinery needs.

- Advanced Coating for Hard Materials:A superhard coating ensures stable machining of challenging materials like titanium alloys and stainless steel, achieving surface roughness levels of ≤Ra0.4.

Why Our Custom Tooling Service Stands Out

Our success is not just about the product—it’s about the partnership and process. Here’s why clients choose us:

- Technical Collaboration:Our engineering team works closely with clients throughout the design and validation process, ensuring the final solution meets production line standards from day one.

- Rapid Response:We streamline the customization process, reducing lead times by an average of 30%—from initial consultation to sample delivery.

- Cost Transparency:We provide clear pricing and lifecycle cost optimization recommendations, eliminating hidden fees and ensuring maximum value for our clients.

Real-World Results: Client Feedback

After implementing the Carbide Reamer 6FL-Coolant , the client reported remarkable improvements in their production process:

- 22% Reduction in Single-Piece Processing Time : Faster machining speeds and optimized tool geometry contributed to significant time savings.

- 40% Decrease in Tool Replacement Frequency : Enhanced durability and cooling technology extended tool life, reducing maintenance costs.

- Consistent Surface Finish : Achieved ≤Ra0.4 surface roughness across all machined parts, meeting stringent quality standards.

- Overall Cost Savings : By improving efficiency and reducing downtime, the client achieved meaningful cost reductions while maintaining high-quality output.

One client commented:

“In our high-volume automotive parts production, this custom reamer has been a game-changer. It has shortened single-piece processing times by 22% and reduced tool replacement frequency by 40%. This is true cost-effectiveness!”

Conclusion: A Tailored Solution for Every Need

The success of the Carbide Reamer 6FL-Coolant demonstrates our commitment to delivering precision-engineered tools that solve real-world challenges. Whether you’re machining titanium alloys, stainless steel, or other high-hardness materials, our custom tooling solutions can help you achieve higher efficiency, better quality, and lower costs.

Partner with SDFTools Today

If you’re facing similar machining challenges or want to optimize your production processes, SDFTools is here to help. Our team of experts will work with you to design and deliver custom tools that meet your unique needs.

🌐 Website: www.sdftools.com

📧 Email: sdfgroup@sdftools.com

📱 WhatsApp: +65 89420188

👥 LinkedIn: www.linkedin.com/company/shengdefu-precision-tools-co-ltd

Let’s collaborate to create cutting-edge solutions that drive your business forward!