Description

Features

Applications

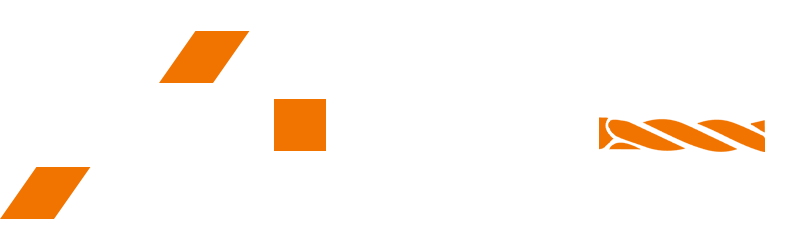

Work Materials

Industrial Parallel Threading Solution

Engineered for high-volume production of hydraulic and pneumatic fittings requiring precise straight threads without taper. Full-tooth design ensures uniform thread depth throughout machining operations.

Manufacturing Excellence

- Advanced Grinding Process: Utilizes 5-axis CNC grinding technology to achieve ±0.005mm pitch accuracy

- Material Selection: Japanese UF10 carbide blanks with 94.5 HRA hardness for superior wear resistance

- Coating Technology: 3.5μm AlCrON coating provides:

- 30% increased lubricity for aluminum alloys

- 950°C thermal barrier for stainless steel

- Quality Control: 100% ZOLLER SmartCheck verification for:

- Pitch accuracy (BS 2779 Class B)

- Runout (<0.015mm)

Performance Versions

- Standard Version: Optimized for general industrial applications (40-80m/min)

- High-Speed Version: Reinforced core for 100+m/min machining of aluminum alloys

Critical Applications

- Hydraulic Systems: SAE J1926 port connections

- Pneumatic Equipment: ISO 1179 air fittings

- Food Machinery: EHEDG-compliant joints

- Semiconductor: Ultra-clean gas line assemblies

Technical Advantages

- Chip Control: 35° helix angle prevents bird-nesting in blind holes

- Surface Finish: Achieves Ra0.8μm on 6061 aluminum

- Tool Longevity: 3X life vs uncoated tools in brass machining

- Compatibility: Universal shank design fits ER/HP coolant holders

Global Availability

- BSPP Series: G1/8″ – G4″

- BSPG Series: R1/8″ – R4″

- Specials: Extra-long reach, metric conversions

| Full-thread British standard pipe thread milling cutter - BSP (G) | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ● = 最佳 Best ○ = 适合 Good | ||||||||||||||||||||||

| P | H | K | M | N | S | |||||||||||||||||

| Carbon Steel | Alloy Steel | Prehardened Steel | ~45HRC | ~55HRC | ~60HRC | ~65HRC | Cast Iron | Stainlee Steels | Aluminium Alloys | Copper Alloys | Plastic Cement | Acrylic | Superalloy | Titanium Alloy | ||||||||

| ● | ● | ● | ● | ● | ● | ○ | ○ | ○ | ● | |||||||||||||

| \ \ Order Number | Specification | P | Φ | H | D | L | F | Stock | ||||||||||||||

| \ \ MP17445ASH-28614N660 | 1/16 | 28 | 6.0 | 14 | 6.0 | 60 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-28814N860 | 1/8 | 28 | 8.0 | 14 | 8.0 | 60 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-19818N860 | 1/4 | 19 | 8.0 | 18 | 8.0 | 60 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-191020N1075 | 1/4 | 19 | 10 | 20 | 10 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-191024N1075 | 1/4 | 19 | 10 | 24 | 10 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-191225N1275 | 3/8 | 19 | 12 | 25 | 12 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-191228N1275 | 3/8 | 19 | 12 | 28 | 12 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-141220N1275 | 1/2 | 14 | 12 | 20 | 12 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-141228N1275 | 1/2 | 14 | 12 | 28 | 12 | 75 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-141630N16100 | 3/4 | 14 | 16 | 30 | 16 | 100 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-111632N16100 | 1” | 11 | 16 | 32 | 16 | 100 | 4 | sufficient | ||||||||||||||

| \ \ MP17445ASH-111638N16100 | 1” | 11 | 16 | 38 | 16 | 100 | 4 | sufficient | ||||||||||||||

| \ \ MP17545ASH-112042N20100 | 1” | 11 | 20 | 42 | 20 | 100 | 5 | sufficient | ||||||||||||||

| Supports Non-Standard Customization | ||||||||||||||||||||||