SDFTools Custom Tooling:Precision and Efficiency Combined

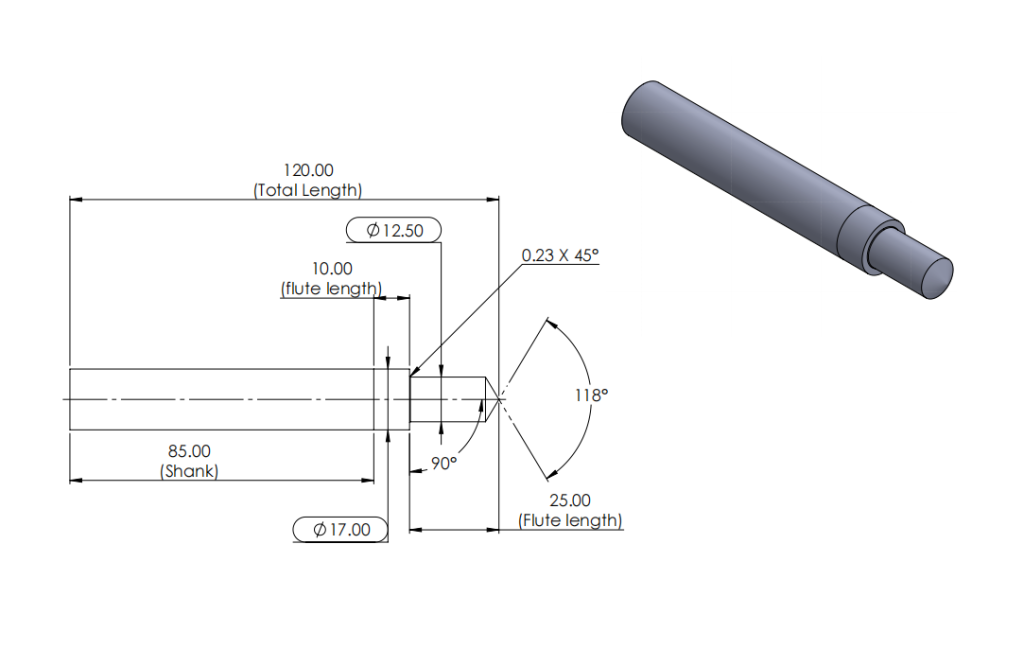

At SDFTools, we specialize in custom-designed internal coolant step drills that streamline your machining process. These tools are engineered to create multi-level step holes and chamfers in a single operation , saving time, reducing tool changes, and ensuring superior surface finishes.

Key Features of Our Internal Coolant Step Drills

✅ Multi-Step Design :

Effortlessly machine complex stepped holes with different diameters in one pass, eliminating the need for multiple tools or setups.

✅ Integrated Chamfering :

The tool is designed to simultaneously add chamfers, further simplifying the machining process and enhancing efficiency.

✅ Internal Coolant Channels :

Delivers coolant directly to the cutting zone, improving chip evacuation, reducing heat buildup, and extending tool life—especially critical for deep-hole or high-speed operations.

✅ Fully Customizable :

From step configurations to specific dimensions, every drill is tailored to meet your unique application requirements.

Applications Across Industries

- Aerospace : Precision machining of lightweight components with stepped features.

- Automotive : Efficient production of engine parts, transmission housings, and structural components.

- Mold Making : Creating molds with multi-level cavities and precise chamfers.

- General Manufacturing : Simplified workflows for custom parts, prototypes, and batch production.

📍 Why Choose SDFTools for Custom Step Drills?

Our non-standard custom tooling solutions combine advanced engineering with precision manufacturing, ensuring your tools deliver unmatched performance. Whether you’re dealing with tight tolerances, difficult materials, or unique geometries, our team is here to support your needs.

📦 Global Delivery Available : Custom tools shipped worldwide with short lead times.

💬 Questions? Let’s Connect!