In modern manufacturing, standard tools often fall short when faced with complex materials and specialized machining requirements. Recently, we successfully provided a custom coolant-through flat bottom step drill to a high-end component manufacturer, helping them overcome multiple machining challenges while significantly optimizing production efficiency and product quality.

Customer Requirements Background

1、Complex Material Characteristics

- The customer primarily machined high-hardness materials such as stainless steel, titanium alloys, and hardened steel, which impose extremely high demands on tool life and machining precision.

- Built-up edges and heat accumulation during machining caused rapid tool wear, leading to low efficiency.

2、Strict Machining Requirements

- The bottom of the holes needed to be smooth and flat to meet the high precision requirements for subsequent assembly.

- Surface roughness had to be controlled within ≤Ra0.8, and hole tolerances could not exceed ±0.01mm.

3、Frequent Issues with Existing Tools

- Standard drills could not achieve zero-deviation machining, resulting in tilted or burr-filled hole bottoms.

- Traditional cooling methods were ineffective, limiting tool life to around 500 holes, and frequent tool changes increased downtime.

4、High Cost of International Brand Solutions

- A global tool manufacturer’s custom solution was priced too high, with a delivery cycle of up to 6 weeks, making it unacceptable for the customer.

Facing these challenges, the customer urgently needed an efficient, stable, and cost-effective customized drill.

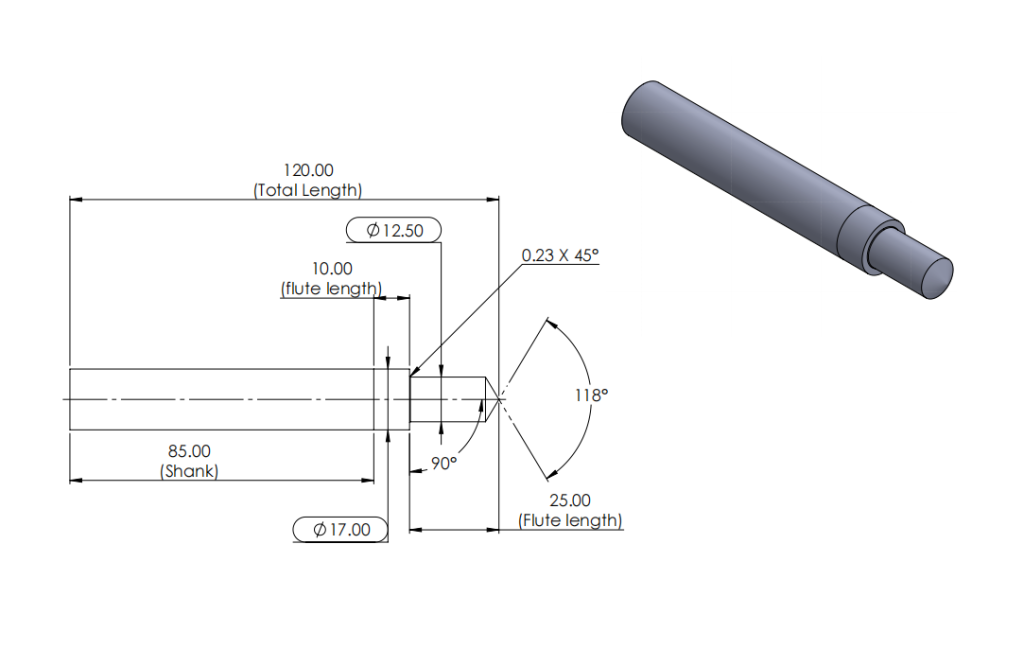

Our Solution: Custom Coolant-Through Flat Bottom Drill

To meet the customer’s specific needs, we designed a coolant-through flat bottom step drill, featuring the following core advantages:

1、Coolant Channel Design

- Coolant is delivered directly to the cutting edge through internal channels, effectively reducing temperature and heat buildup.

- This design extended tool life by over 3 times, significantly lowering maintenance costs.

2、Advantages of Flat Bottom Drills

- The flat bottom design enables zero-deviation machining, producing smooth and flat hole bottoms on curved, inclined, or thin plate surfaces.

- It is particularly suitable for hard materials like stainless steel, titanium alloys, and hardened steel, ensuring stable and reliable machining quality.

3、Highly Customizable

- Based on the customer’s material properties, machine parameters, and coating requirements, we provided exclusive tool designs.

- Tool geometry angles, edge honing, and coating types can all be adjusted according to actual application needs, ensuring optimal performance.

Actual Results: Customer Feedback and Achievements

After practical testing and batch production verification, this coolant-through flat bottom step drill demonstrated outstanding performance:

- Tool Life Extension: Tool life increased from 500 holes to over 1,500 holes, reducing tool replacement frequency by 70%.

- Improved Machining Efficiency: With coolant reaching the cutting point, chip evacuation became smoother, reducing cycle times by 25%.

- Stable Machining Quality: Hole bottoms were smooth and flat, with surface roughness ≤Ra0.8 and hole tolerances controlled within ±0.01mm.

- Lower Overall Costs: Single-hole machining costs decreased by 40%, saving significant expenses for the customer.

The customer highly praised this custom drill and expressed their intention to continue collaborating with us on developing more customized tools.

Why Choose SDFTools?

1、Deep Customization Capability

- We provide end-to-end services from design to production based on specific customer needs, ensuring each tool perfectly fits its application.

2、Professional Technical Support

- Our engineering team has extensive industry experience and can quickly respond to customer needs, offering optimal solutions.

3、High-Quality Manufacturing

- Advanced processing technologies and strict quality control systems ensure each tool delivers exceptional performance and reliability.

Contact Us to Customize Your Perfect Tool!

If you face similar machining challenges or wish to optimize your current production process, feel free to contact us! SDFTools will provide professional technical support and customized tooling solutions.

🌐 Website: www.sdftools.com

📧 Email: sdfgroup@sdftools.com

📱 WhatsApp: +65 89420188

👥 LinkedIn: www.linkedin.com/company/shengdefu-precision-tools-co-ltd

Let’s build a more efficient and precise machining future together!