In the field of precision machining, standard tools often struggle to meet the unique needs of complex materials and specialized processes. Recently, we successfully developed a custom step drill (Customized Carbide Step Burnishing Drill) for a high-end manufacturing company. This tool helped them overcome challenges in machining aluminum alloy castings, such as low efficiency and insufficient hole diameter accuracy, while significantly enhancing production performance.

Customer Requirements Background

1、Complex Workpiece Structure

- The customer primarily machined aluminum alloy castings, which included multiple areas requiring high-precision hole diameters. Some holes needed to be completed in a single operation with multiple stepped levels.

- Hole tolerance requirements were strict, needing to be controlled within ±0.005mm, with a surface roughness of ≤Ra0.8.

2、Frequent Issues with Existing Tools

- Standard drills often deviated during machining, leading to unstable hole diameter accuracy and an inability to achieve multi-level stepped holes in one operation.

- Limited coolant cooling effectiveness resulted in tool life being only around 500 holes, with frequent tool changes increasing downtime.

3、High Cost of International Brand Solutions

- A global tool manufacturer’s custom solution was priced too high, with a delivery cycle of over 6 weeks, making it unacceptable for the customer.

Facing these pain points, the customer urgently needed an efficient, stable, and cost-effective customized step drill.

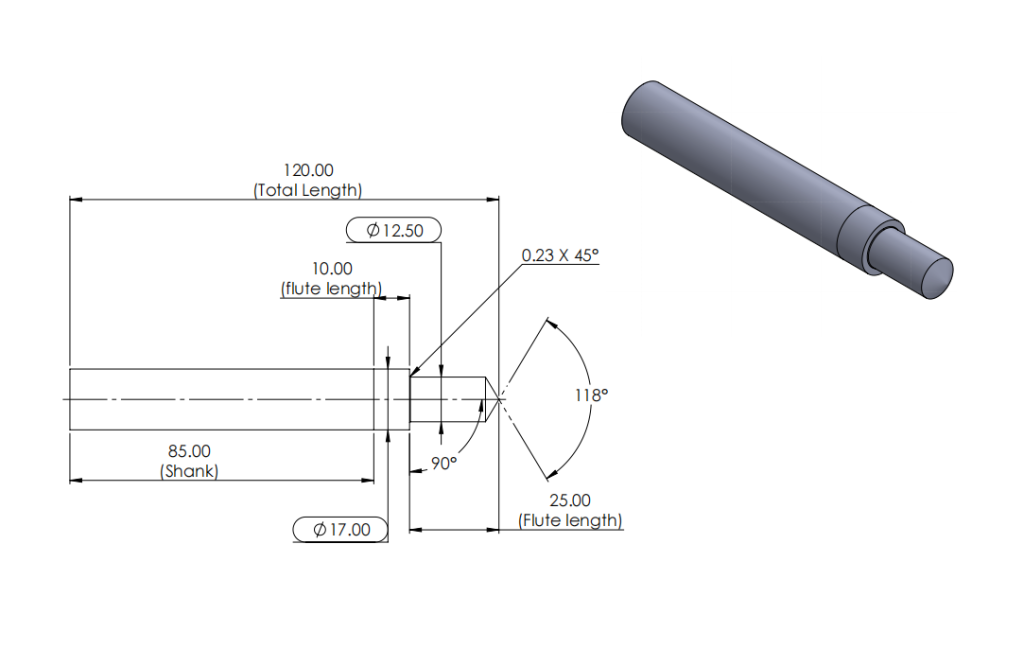

Our Solution: Custom Step Drill

To address the customer’s specific needs, we designed a custom step drill, featuring the following core advantages:

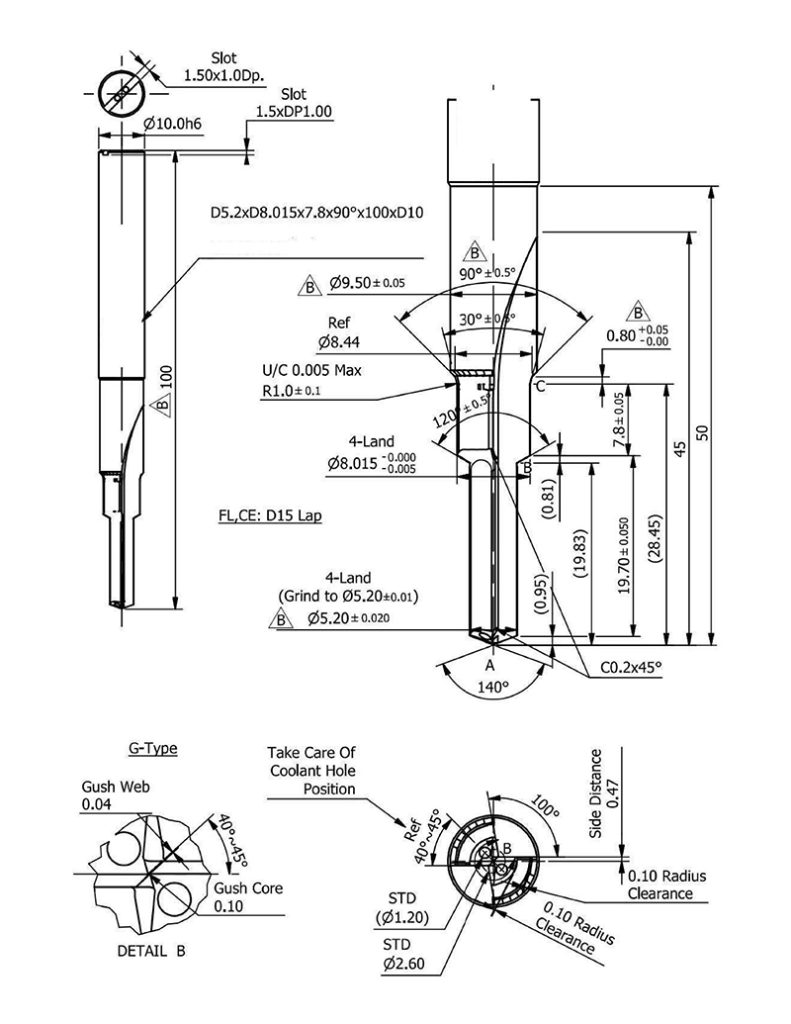

1、Internal Coolant Channel Design

- The tool is equipped with internal coolant channels that directly deliver coolant to the cutting point, effectively reducing temperature and heat buildup.

- This design extended tool life by over 3 times, significantly lowering maintenance costs.

2、Step Drill Functionality

- By optimizing the tool’s geometry, it achieves multi-level stepped holes in a single operation, significantly improving machining efficiency and reducing tool changes.

- It is particularly suitable for materials like aluminum alloys, which are prone to built-up edges, ensuring stable and reliable machining quality.

3、High-Precision Design

- Tool diameter precision reaches D8.015-0.005, ensuring hole tolerances are strictly controlled within ±0.005mm.

- Surface treatment uses grinding technology (Grind to 05.20±0.01), further enhancing tool wear resistance and machining accuracy.

4、High Adaptability and Customization

- Based on the customer’s material properties, machine parameters, and coating requirements, we provided exclusive tool designs.

- Tool geometry angles, edge honing, and coating types can all be adjusted according to actual application needs, ensuring optimal performance.

Actual Results: Customer Feedback and Achievements

After practical testing and batch production verification, this custom step drill demonstrated outstanding performance:

- Tool Life Extension: Tool life increased from 500 holes to over 1,500 holes, reducing tool replacement frequency by 70%.

- Improved Machining Efficiency: Multi-level stepped holes achieved in a single operation significantly shortened cycle times, improving overall efficiency by 25%.

- Stable Machining Quality: Hole tolerances were strictly controlled within ±0.005mm, with surface roughness ≤Ra0.8, fully meeting customer requirements.

- Lower Overall Costs: Single-hole machining costs decreased by 35%, saving significant expenses for the customer.

The customer highly praised this custom step drill and expressed their intention to continue collaborating with us on developing more customized tools.

Why Choose SDFTools?

1、Customization Capability

- We provide end-to-end services from design to production based on specific customer needs, ensuring each tool perfectly fits its application.

2、Rapid Response and Technical Support

- Our engineering team is fully involved in design validation, ensuring solutions are quickly implemented and meet production line standards.

3、High-Quality Manufacturing

- Advanced processing technologies and strict quality control systems ensure each tool delivers exceptional performance and reliability.

Contact Us to Customize Your Perfect Tool!

If you face similar machining challenges or wish to optimize your current production process, feel free to contact us! SDFTools will provide professional technical support and customized tooling solutions.

🌐 Website: www.sdftools.com

📧 Email: sdfgroup@sdftools.com

📱 WhatsApp: +65 89420188

👥 LinkedIn: www.linkedin.com/company/shengdefu-precision-tools-co-ltd

Let’s build a more efficient and precise machining future together!