Description

Features

Applications

Work Materials

Revolutionizing External Thread Manufacturing

Unlock unprecedented efficiency in shaft threading with our specialized external thread mills – engineered to deliver perfect threads in a single pass while eliminating deflection issues common in conventional methods.

Engineering Excellence

- Anti-Deflection Geometry: 25° radial relief angle minimizes cutting forces

- Material Innovation: Japanese TUNGALOY® carbide with 93.8 HRA hardness

- Coating Breakthrough:

- AlCrON Pro (3.5μm thickness | 3,200HV)

- 40% lower friction coefficient vs standard coatings

- Precision Assurance: 100% ZOLLER verification for:

- Profile accuracy ±0.003mm

- Runout <0.02mm

Performance Versions

- Standard Edition: Carbon steel shafts at 60-100m/min

- High-Performance Edition: Titanium/Inconel shafts at 30-50m/min

Industry-Leading Applications

- Automotive: Crankshaft M24x3 threads in 42CrMo4

- Robotics: Harmonic drive components in 17-4PH

- Wind Energy: Tower flange bolts in S355J2

- Medical: Implant connector threads in Ti-6Al-4V

Technical Superiority

- Chip Control: Helical flute design prevents chip wrapping

- Surface Quality: Achieve Ra0.4μm on 304 stainless steel

- Tool Longevity: 2.5X life vs competitors in continuous machining

- Speed Advantage: 30% faster than single-point threading

European Standard Mastery

- Standard Series: M4-M68 (DIN 13-1 to DIN 13-50)

- Fine Pitch Series: M8x1 to M56x2

- Special Configurations: Left-hand, multi-start, custom lengths

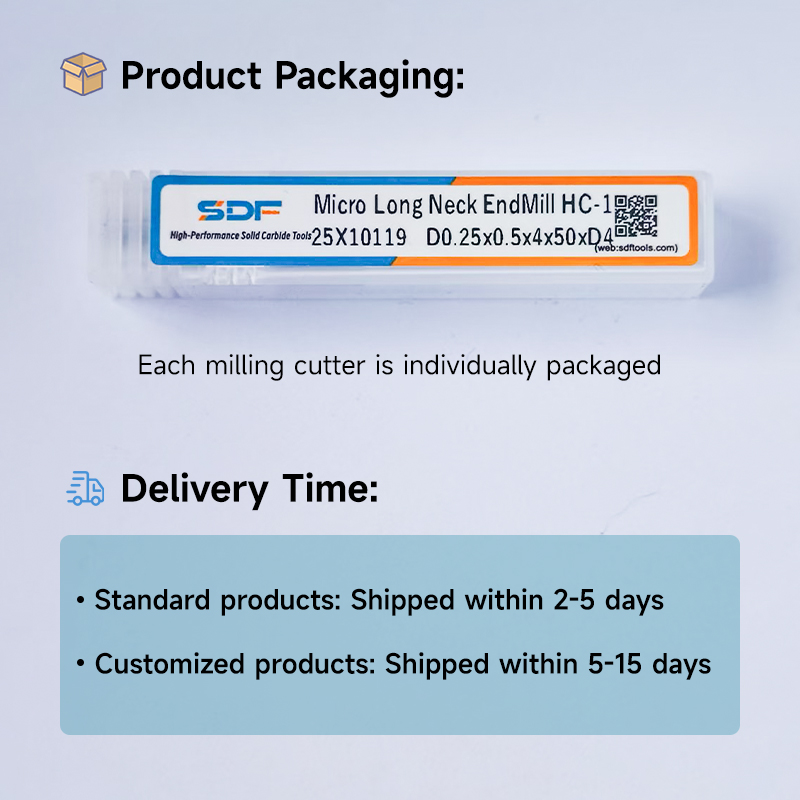

| Full-thread metric external thread milling cutter for steel (02) | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ● = 最佳 Best ○ = 适合 Good | |||||||||||||||||||||||

| P | H | K | M | N | S | ||||||||||||||||||

| Carbon Steel | Alloy Steel | Prehardened Steel | ~45HRC | ~55HRC | ~60HRC | ~65HRC | Cast Iron | Stainlee Steels | Aluminium Alloys | Copper Alloys | Plastic Cement | Acrylic | Superalloy | Titanium Alloy | |||||||||

| ● | ● | ● | ● | ● | ● | ○ | ○ | ○ | ● | ||||||||||||||

| Order Number | Specification | P | Φ | H | D | L | F | Stock | |||||||||||||||

| \ \ MP17445ASH-051024N10752 | M12 | 0.5 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-0751024N10752 | M12 | 0.75 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-101024N10752 | M12 | 1.0 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-1251024N10752 | M12 | 1.25 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-151024N10752 | M12 | 1.5 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-1751024N10752 | M12 | 1.75 | 10 | 24 | 10 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-11228N12752 | M14 | 1 | 12 | 28 | 12 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-151228N12752 | M14 | 1.5 | 12 | 28 | 12 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-211628N12752 | M14 | 2 | 11.6 | 28 | 12 | 75 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-151432N141002 | M16 | 1.5 | 14 | 32 | 14 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-21332N141002 | M16 | 2 | 13 | 32 | 14 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-2514838N161002 | M18 | 2.5 | 14.8 | 38 | 16 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-11638N161002 | M20 | 1 | 16 | 38 | 16 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-151638N161002 | M20 | 1.5 | 16 | 38 | 16 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-251642N161002 | M20 | 2.5 | 16 | 42 | 16 | 100 | 4 | sufficient | |||||||||||||||

| \ \ MP17445ASH-31642N161002 | M24 | 3 | 16 | 42 | 16 | 100 | 4 | sufficient | |||||||||||||||

| 支持非标定制(Supports Non-Standard Customization) | |||||||||||||||||||||||