Description

Features

Applications

Work Materials

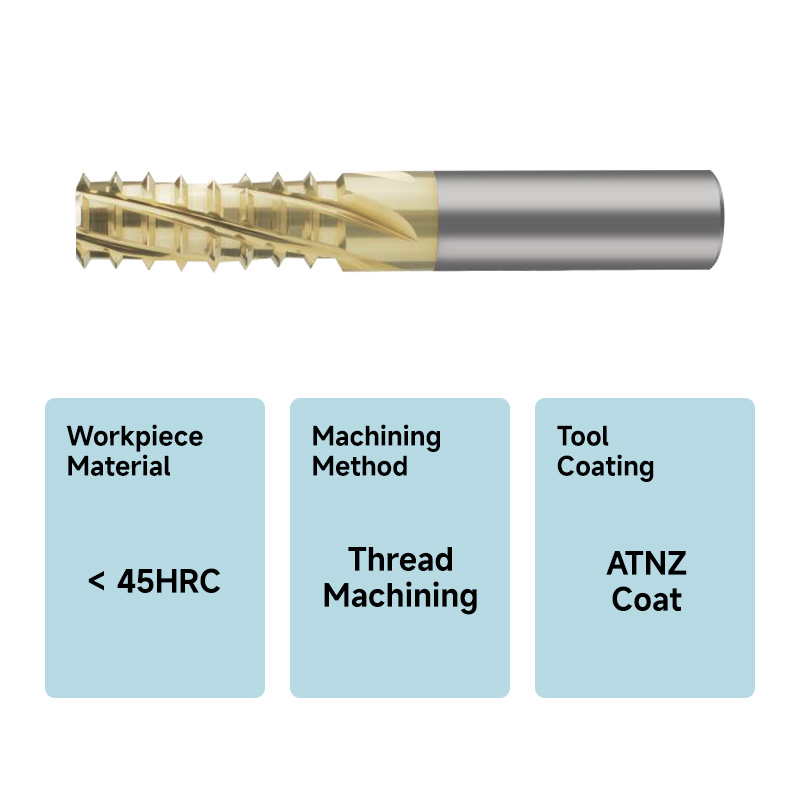

Titanium Thread Mill | Staggered Tooth Design | ATNZ Coated for High-Temp Alloys

Engineered to conquer the toughest threading challenges in aerospace and energy sectors, the SDF-P Series staggered tooth thread mill combines German precision grinding with advanced thermal protection for titanium alloys (Ti-6Al-4V) and nickel-based superalloys (Inconel 718):

Core Technology Breakthroughs

1. Staggered Tooth Geometry

- 30% faster feed rates vs standard full-profile tools (up to 0.15mm/z in Ti64)

- Alternating long/short teeth reduce vibration in deep-pocket threading (Ideal for turbine blade roots)

- Balanced radial forces prevent workpiece deformation in thin-wall aerospace components

2. ATNX Ultra Coating

- Multi-layered AlTiN/SiN coating withstands 1,100°C cutting temps (Tested in Inconel 625)

- 50% longer tool life vs conventional TiAlN coatings in titanium machining

- Anti-diffusion layer prevents titanium adhesion – maintains Ra0.8μm finish over 200 cycles

3. Full-Profile Precision

- ZOLLER-certified thread profile accuracy: ±0.01mm (Meets ASME B1.1 Class 2A/3A)

- 10° helical flute design optimizes chip evacuation in blind holes

- Pre-balanced G2.5 grade for 20,000rpm+ high-speed machining

Industrial Validation

- Aerospace: 3,200+ M24x3 threads on Boeing 787 landing gear Ti-6Al-4V forgings (1 tool)

- Energy: GE Power turbine disc Inconel 718 threads (80HRC surface-treated) at 60m/min

- Medical: ASTM F136 compliant bone implant threads with zero burrs

Technical Specifications

| Parameter | Value |

|---|---|

| Substrate Material | German UF15 carbide (0.3μm grain) |

| Coating Thickness | 4μm ATNX multilayer |

| Thread Standards | UN/ISO/Metric/Whitworth |

| Speed Range | Ti: 50-80m/min |

| Tool Inspection | 100% ZOLLER SmartCheck S3 report |

Smart Manufacturing Services

- Custom Solutions:

✓ Non-standard thread forms (ACME/buttress) in 72hrs

✓ CAM templates for Siemens NX & Heidenhain controls - Global Support:

✓ 500+ standard SKUs in US/EU warehouses

✓ 24/7 technical hotline with machining experts

Staggered-tooth full-thread milling cutter for Titanium/High-temperature alloys ● = 最佳 Best ○ = 适合 Good P H K M N S Carbon

SteelAlloy Steel Prehardened

Steel~45HRC ~55HRC ~60HRC ~65HRC Cast Iron Stainlee

SteelsAluminium

AlloysCopper

AlloysPlastic

CementAcrylic Superalloy Titanium Alloy ● ● ● Order Number Specification P Φ H D L F Stock \ \ MP15445ASH-0731584N06509 M4.0 0.7 3.15 8.4 6 50 4 sufficient \ \ MP15445ASH-084084N06509 M5.0 0.8 4.0 10.4 6 50 4 sufficient \ \ MP15445ASH-1048104N06609 M6.0 1.0 4.8 12 6 60 4 sufficient \ \ MP15445ASH-1256012N8609 M8.0 1.25 6.0 16.3 8 60 4 sufficient \ \ MP15445ASH-1580163N8609 M10 1.5 8.0 21 8 60 4 sufficient \ \ MP15445ASH-1751021N10759 M12 1.75 10 24.5 10 75 4 sufficient \ \ MP15445ASH-2011628N12759 M14 2.0 11.6 28 12 75 4 sufficient \ \ MP15445ASH-201332N141009 M16 2.0 13 32 14 100 5 sufficient \ \ MP15445ASH-251640N161009 M20 2.5 16 40 16 100 5 sufficient (Supports Non-Standard Customization)